Cost reduction in electronic systems starts with cooling

EKL Full Service for cost-optimised solutions from idea to delivery

The development of electronic heat sinks in consideration of design-to-cost and design-to-manufacturing is one of our basic principles. By focusing on process cost optimisation, EKL actively supports you in reducing your manufacturing costs without compromising quality or performance. Product cost reduction is another important aspect that we achieve through efficient design, careful material selection and reliable manufacturing partners.

Heat sink development with a view to life cycle costs

Our life cycle cost optimisation with regard to your component cooling takes into account not only the initial manufacturing costs, but also the costs for maintenance and operation over the entire service life of the cooling solution. With a view to the total cost of ownership (TCO), we include the direct and indirect costs incurred during the service life of a cooling system in our proposed solution with the aim of achieving a comprehensive cost reduction. These strategic approaches enable us to provide you - as a manufacturer of electronic devices - with high-quality cooling solutions that are cost-efficient and can be easily integrated into your production processes. Right through to the delivery of pre-assembled and tested assemblies to further reduce assembly work in your own production line.

Let's talk about your cooling task!

Lynne Albring

Sales Department

+49 (0)7561 9837-50

l.albring@ekl-ag.de

Make an appointment Enquiries by e-mail

Lynne Albring

Sales Department

+49 (0)7561 9837-50

l.albring@ekl-ag.de

Make an appointment Enquiries by e-mail

Our mission: Your product success

Open and honest advice right from the start

At the start of a project, we are happy to talk to you to get to know your specific application and all environmental variables as well as possible. If, in our experience, the heat sink you have in mind cannot cope with the heat generated by your components, we will tell you so. In this way, we not only protect your development budget, but also the high level of customer satisfaction that we have built up over 30 years.

Thinking along with concepts and ideas

Include us in your system concept as early as possible! Because with our advice, we can provide useful impulses to optimise the board layout and housing design for cooling. Even small changes to the arrangement of components in the device are often enough to ensure better ventilation and heat dissipation. Or a housing cooler is better suited than a housing fan to overcome your heat problem in this application. As a result, smaller or simpler heat sinks may be an option, which can have a direct impact on unit costs and your assembly labour.

Feasibility studies for the technical and economic validation of heat sink calculations

Do you prefer facts over phrases for your system development? We do too! The EKL feasibility study provides sound advice on efficient heat dissipation. Our in-house design department not only prepares heat sink calculations, but can also back them up with thermodynamic simulations. This increases the expected reliability and service life of your electronic components and therefore saves costs in the long term.

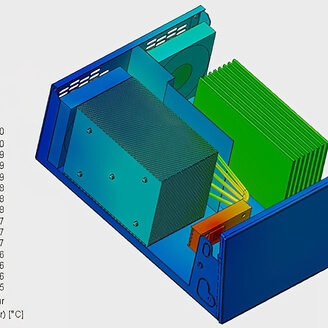

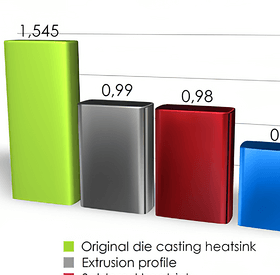

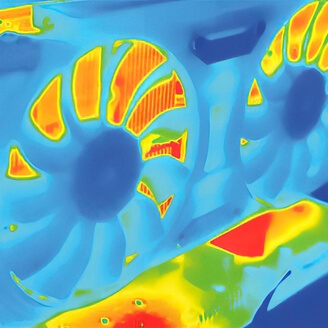

Thermal simulations of alternative heat sink designs

By utilising our simulation software, thermodynamic data can be used to calculate heat sinks in order to find the most effective component cooling without the need to produce costly prototypes. This allows us to accurately predict cooling performance and helps to optimise material and manufacturing costs before they are incurred.

Functional prototypes and design prototypes

Prototypes are the crucial step between design and series production. They allow problems to be identified and solved at an early stage, which prevents costly heat problems in the series device. At EKL, we have our own 3- and 5-axis CNC production and mechanical design facilities to build prototypes in-house at short notice. Of course, close-to-series heat sink prototyping is also available.

By using functional prototypes, your engineers can test and, if necessary, optimise the functionality and design before device production. This minimises the risk of warranty claims and reduces overall costs. Design prototypes in turn support the aesthetic and ergonomic design. You can use them at your presentations and trade fair appearances to test acceptance and thus support the success of the market launch and the product itself.

By using functional prototypes, your engineers can test and, if necessary, optimise the functionality and design before device production. This minimises the risk of warranty claims and reduces overall costs. Design prototypes in turn support the aesthetic and ergonomic design. You can use them at your presentations and trade fair appearances to test acceptance and thus support the success of the market launch and the product itself.

Manufacturing expertise

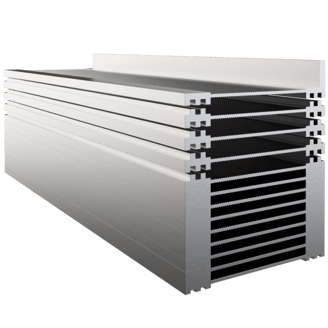

Free choice in manufacturing technologies and in the combination of cooling technologies

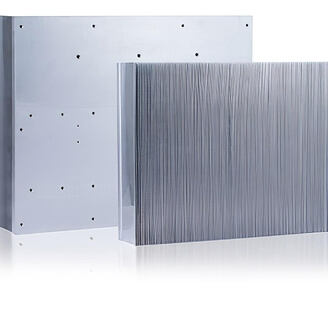

As a long-standing heat sink manufacturer, EKL has practically all the manufacturing processes available on the market to design your heat sink ideally in terms of price and performance.

Close-to-series prototypes for real-time functional tests

For final verification before series production, we offer the production of prototypes that are already almost identical to the series parts. As individual items, they correspond to the end product in terms of shape, design and manufacture. This allows your development department to test the device in real-time operation at full load and/or in adverse environmental situations in order to finally confirm that the cooling solution is ready for series production.

Top quality produced in series at favourable prices

The cost-effective production in Asia and the associated low tooling costs make it possible to supply small (from 100 units) and medium series up to large series (100,000 units and more) of an individually optimised cooler. We work exclusively with long-term manufacturing partners who impress with their consistently high production quality.

Not only chic with surface finishing, but also attractive in terms of efficiency

The primary purpose of anodising, powder coating or painting is to protect your heat sinks from corrosion and environmental influences. However, black anodising, for example, also makes the heat sink not only stylish, but also efficient! Compared to a silver heat sink, black heat sinks can convert significantly more object heat into radiant heat and increase convection.

Quality assurance through in-house test laboratories

At EKL, we combine the high quality standards of German products and engineering skills with favourable production costs in Asia. All development takes place in Germany and all series products are randomly tested by our German test laboratory using state-of-the-art methods before they are kept in our German warehouses ready for your production.

Delivery expertise

Pre-assembled assemblies to speed up your production processes

We actively assist your production staff by supplying pre-assembled assemblies. Your components are already pre-assembled with the heat sink. This not only reduces your labour costs per device, but also guarantees the highest quality.

Transport-safe packaging design

EKL develops the packaging design itself and has the customised packaging produced for you. In this way, we protect your sensitive heat sinks or assemblies so that they are not damaged during the "rough" transport business. We also pay attention to sustainability: on request, we can already pack your products in your returnable packaging to relieve your internal logistics processes.

Consignment warehouse in Germany with optimised logistics

With over 1100 storage locations in Leutkirch im Allgäu, we offer you customised logistics solutions and reduce your storage costs:

- Stocking close to production and consignment stock

- Just-in-time deliveries

- Co-ordinated delivery schedules

- Flexible shipping options for individual requirements: express special deliveries, overnight service, parcel shipping, pallet deliveries

Get to know further EKL expertise

EKL - Everything from a single source

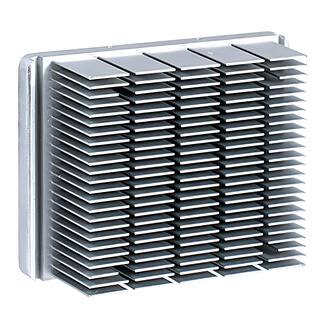

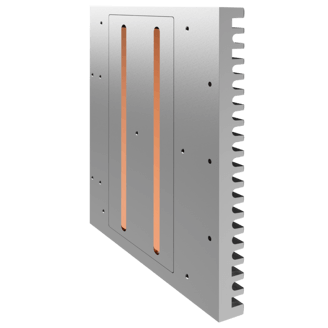

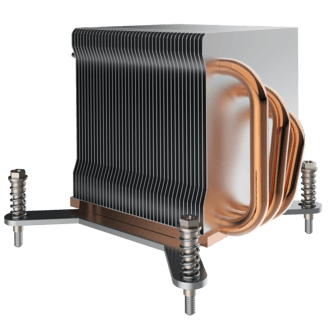

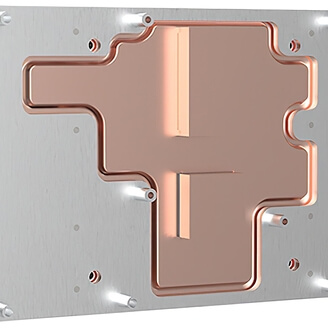

The temperature of electronic components must remain within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL provides you with expert support in solving these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management technologies.

EKL is therefore your perfect solution partner for cost-optimised temperature regulation of all components in your electronic device. We are at your side in every project phase, from the initial idea, design and prototype construction through to series production - and beyond!

The temperature of electronic components must remain within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL provides you with expert support in solving these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management technologies.

EKL is therefore your perfect solution partner for cost-optimised temperature regulation of all components in your electronic device. We are at your side in every project phase, from the initial idea, design and prototype construction through to series production - and beyond!

Personal point of contact

From the initial project phase to the delivery of your customised cooling technology, you will always have a personal point of contact at EKL We are always available to provide you with competent and responsive support.

Full service from the idea to logistics

Concentrate your core competence on product development. We offer all project services relating to cooling - from the initial consultation, idea development and thermal simulation, prototype construction and optimisation, through to punctual delivery and reliable logistics and warehousing.

Variety of manufacturing technologies

We are one of the heat sink manufacturers with the widest range of manufacturing technologies. This enables us to offer a service portfolio that is designed for the development and production of your truly best cooling solution - at an excellent price-performance ratio.

Performance optimisation + cost optimisation

EKL actively supports you in reducing your manufacturing costs without compromising quality or performance. Product cost reduction is an important aspect that we achieve for you through efficient design, careful material selection and reliable manufacturing partners.

Pre-assembled assemblies + packaging

We actively assist your production staff by supplying pre-assembled assemblies. This not only reduces your labour costs per device, but also guarantees the highest quality. Your sensitive heat sinks or assemblies are protected for transport using customised packaging.

Warehouse and logistics in Germany

With over 1100 pallet spaces, we offer tailor-made logistics solutions and minimise your storage costs through stockpiling and consignment stock, just-in-time deliveries, coordinated delivery schedules and flexible shipping options for individual requirements.

Let's talk about your cooling task!

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail